What Size Finish Nail For Exterior Trim

one / 15

Which nailer does what?

The basics

Trim nailers are categorized by the thickness or "gauge" of the nails they shoot: The bigger the gauge number, the smaller the nail (seems astern, doesn't it?). Nailers that shoot the biggest trim nails—xv and xvi judge—are usually called "end nailers." Midsize 18-guess nailers are chosen "brad nailers." The smallest nailer, the 23-judge, is unremarkably called a "pinner" or "micro pinner."

xv-guess end nailer

This is the gun I unremarkably grab for nailing large 3/4-in.-thick baseboard and trim. It'southward also a good choice for more demanding jobs like nailing doorjambs or stair treads. These nailers take a large piston, and because of the extra bulk, often accept angled magazines so you tin can get into tight spots. Name-brand 15-gauge nailers, which handle boom lengths up to 2-1/2 in., offset at less than $200.

xvi-guess finish nailer

Similar xv-guess nailers, near 16-estimate guns shoot nails up to ii-one/2 in. long and are suitable for thick trim. The main reward of a 16-gauge gun is that it's smaller and lighter. If you're shopping for a stop nailer, I'd recommend the larger 15-gauge gun, simply considering the fatter nails provide more holding power. Simply some carpenters disagree with me. Y'all'll pay most the same for a name-brand sixteen-guess nailer every bit you would for a fifteen-gauge gun.

18-gauge brad nailer

If you lot plan to buy only i trim nailer, this is the size to become. I utilise mine more than than all my others combined. It's perfect for standard trim, piece of furniture making and odd jobs around the shop. Models that shoot brads up to i-1/iv- in. are common, but I strongly recommend spending a few bucks more for a gun that tin handle brads up to 2 in. long. Name-brand two-in. guns start under $100.

23-gauge pinner

This is the nailer I utilise the to the lowest degree. Those tiny pins merely don't have enough property strength for well-nigh jobs. But don't get me incorrect—at that place are times when pins are perfect, especially to boom small parts. My pinner, which cost a lilliputian over $100, shoots pins ranging from one/ii to 1 in. long. That's long plenty for nearly jobs, though I occasionally wish I had a model that could handle pins upwards to two in. long, which would cost $225 or more.

Fasteners

Smaller-judge nails usually come in packs that load vertically. 16-gauge nails usually come in packs that load at an angle.

two / fifteen

Use a block to button baseboard

When baseboard—or the floor—isn't straight, I forcefulness the trim downwards with a 2×4 cake. The block gives me a broad surface to push confronting and lets me apply a lot more pressure. This trick also works with uncooperative crown molding.

iii / 15

Utilise nails earlier screws

I always found information technology difficult to keep parts aligned when screwing cabinets together. Then I discovered that a couple of shots with my stop nailer or brad nailer will keep the parts aligned while I drill pilot holes and drive screws for potent joints.

four / fifteen

Tongue-and-groove the easy way

With a trim nailer, you can install natural language-and-groove paneling in a fraction of the time. Some carpenters utilise a finish nailer for this, but I similar to use my smaller, lighter 18-gauge brad nailer, specially on ceilings. Brads don't have the holding power of xv- or xvi-gauge nails, of course, but I make up for that past shooting two brads into every stud or joist.

Easy on old walls

I do a lot of work in old houses. And hammering nails through those sometime plaster walls is a recipe for cracks. A trim nailer, on the other paw, drives nails instantly, without the repeated blows that tin can cause cracks. I like my 15-gauge nailer all-time for these jobs; the nails are stout enough to push through the hard plaster and long enough to bite into the framing behind information technology.

5 / fifteen

Pre-finish parts

One of the best things about trim nailers is that you don't have to worry virtually beating up the wood, dissimilar with a hammer. That means you can finish parts before assembly. I especially similar to stop trim before installation, which gives me ameliorate results in less fourth dimension. Simply exist sure that the soft rubber tip that came with your nailer is actually on the gun before yous shoot.

6 / xv

Invisible nail holes with a pinner

Pins are tiny and headless, so they're difficult to see fifty-fifty before you fill up them. Afterward, nobody but you will know they're there.

7 / 15

Tight spot? Use a Pinner

The working end of my pinner is only 6-three/eight in. long and goes where none of my other nailers fit.

8 / 15

A pinner ways no splitting

A 23-gauge pinner almost never splits wood, even on very small parts. In most situations, I like to dab on a little wood glue to give the articulation more forcefulness than pins alone can provide.

nine / 15

Pinners are perfect for crafts

I brand a lot of gifts for friends and family unit. My pinner is the go-to tool for frail assemblies like these and saves me the torture of gift shopping.

10 / 15

Nail before you clamp

With a coat of slippery glue, parts will slide out of alignment while you're desperately trying to clamp them. My solution is to tack the parts together with a couple of nails. That keeps the parts aligned while I apply serious pressure with clamps.

11 / fifteen

Tack trim for marking

To eliminate measuring errors, I similar to concur trim in place to mark the length. When the piece is too long to hold alone, I tack one end to the wall with a brad blast. Then I marker, yank the trim off the wall and remove the brad. (I use nippers to pull the brad through the back of the trim to avoid damaging the face of the trim.) That gives me an authentic cut marker and just one extra nail hole to fill later.

12 / 15

No stud? No problem

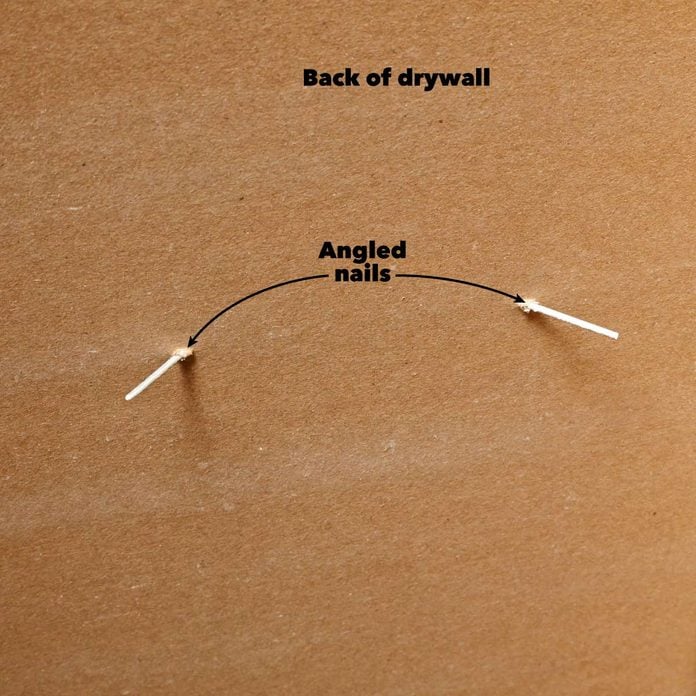

Studs aren't always located where nosotros need them. When I need to nail trim where there's no stud, I dab some construction agglutinative on the back of the trim and and so drive nails into the drywall at 45-degree angles. That holds the trim tight against the wall while the adhesive cures. This "trap nailing" technique works fine with brad nailers and even ameliorate with finish nailers.

xiii / 15

Extend your accomplish

Starting a nail with a hammer takes both easily and that limits your attain. So I used to spend more time moving my ladder than driving nails when I was installing crown molding. A trim nailer, on the other hand, lets me reach way over to shoot a nail. And using a bench, rather than a ladder, lets me nail off even the longest runs in but 2 or three moves. My aluminum bench (Werner AP-twenty) cost well south of a hundred bucks online.

14 / 15

Position parts with a estimate

With a nailer in one hand and a gauge in the other, you can position parts perfectly—without measuring or marking. A combination square is a precise, adaptable approximate, but I frequently make a custom judge merely past tacking a couple of wood scraps together.

xv / xv

Dealing with devious nails

My merely gripe about trim nailers is "blowout." Devil-may-care aim is sometimes the cause, but other times the smash inexplicably takes a plow inside the forest and pops out. When this happens, I take hold of a hammer and try to bulldoze the blast up and then I can grab the caput with pliers and pull it out. This often works with 15- or 16-approximate nails, simply eighteen-gauge brads nigh always bend when I effort to bulldoze them back. In that example, my only solution is to grab the blast with pliers, bend it back and forth until it breaks off, and sink the remainder of the smash with a nail set.

Originally Published: June 28, 2019

Source: https://www.familyhandyman.com/list/finish-nailer-tips/

Posted by: linauntess.blogspot.com

0 Response to "What Size Finish Nail For Exterior Trim"

Post a Comment